If you’re a project manager in the construction industry, it’s safe to assume you know that under-managed vendors lead to hindered productivity and project delays, increasing inefficiencies and costs.

When using a variety of different vendors, it’s critical to provide ongoing management to understand if things are working as they should or if you need to find a replacement.

So, how do you develop a foolproof process for managing vendors? Our checklist below will walk you through best practices to help guide your management strategy and keep your vendors, and project, on track.

Set (and Reinforce) Clear Expectations

Throughout the vendor selection process, it’s important to clearly define the business goals and expectations. Let the vendors know what your current and future requirements are and how they align with your organization’s objectives.

Once you hire a vendor, establish a rhythm and agenda for mandatory meetings throughout the project. Regular communication will help drive vendor accountability and ensure that project priorities are understood and on track. Clearly defined goals combined with consistent communication throughout the project will help you reduce risks related to vendor compliance, collaborate better, and effectively monitor vendor performance.

Use a Vendor Management System

Vendors are critical to the success of your company, helping drive new growth and ensuring you achieve your revenue and profit goals.

A Vendor Management System helps you take care of the activities involved in the end-to-end vendor management process, from initial research and sourcing vendors to managing relationships and evaluating performance. With a VMS you can:

- Mitigate risks: Track your suppliers and provide the data you need to identify supplier threats so you can take necessary steps to alleviate them.

- Optimize performance: Once you have a supplier active in your vendor management system, track and measure performance against the contract to ensure the company is meeting your needs.

- Reduce Costs: With increased visibility, you can see invisible costs, effectively negotiate better rates, and have access to discounts and incentives that can increase your margin.

- Increase administrative efficiencies: Having one central place for all of your vendor data will help you manage your relationships with heightened organization and cut down on data loss and manual errors.

Taking a strategic approach to effectively manage your suppliers will allow you to improve operations and get the best bang for your buck.

Set Realistic and Achievable Deadlines

Given the set of goals and expectations you have, it’s important to set deadlines upfront that are realistic and achievable for your vendors. Setting impossible deadlines not only impedes vendor performance and value creation, but it also increases risk and prevents meaningful collaboration.

Partnering with a company that has an abundance of un-utilized capacity to service customer orders with quick turn-around times will allow you to get ahead of deadlines and avoid delays.

Establish KPI’s to Monitor Vendor Performance

How do you track if your vendors are delivering on the set expectations and business goals? It’s crucial to establish Key Performance Indicators (KPIs) to measure vendor progress and ultimately know if your vendor management process is effective.

A balanced scorecard is an ideally structured methodology that gauges how a vendor’s performance is helping achieve the business goals of your organization. The strategy examines four elements of performance: relationship, cost management, quality, and delivery.

Common questions to ask yourself when deciding performance for each element include:

- Relationship: Is the vendor able to respond to unanticipated demand or modify orders to meet your needs? Is there flexibility in the contract terms and conditions? Does the vendor offer ease of negotiation?

- Cost Management: How often does the vendor raise their prices? Can economies of scale be leveraged to optimize pricing for materials? Can contract management be employed to negotiate better terms on price or increased service quality?

- Quality: Are the materials of the proper grade and value for use in production? How often is there an issue with inferior materials, or simply the wrong materials, being sent?

- Delivery: Do shipments arrive intact and on-time? Does the vendor have the capacity to scale for larger and emergency orders? How often are materials lost, delayed, or damaged?

Reviewing each supplier with hard data to back up your evaluation makes communication between vendors much more productive and helps shift the focus to project improvement and away from arbitrary complaints.

Assess Vendor Risk Regularly

To truly protect your organization, it’s crucial you perform regular vendor risk assessments to ensure they are managed and monitored over time. Start by identifying a comprehensive list of potential hazards and their likely affects and measure and prioritize them. Potential risks include financial status, safety protocols, security breaches, legal and regulatory compliance, and reputation.

Here are a few key times to perform risk assessments:

- Pre-Hire Risk Reviews: Introduce risk reviews to vendors during the request-for-proposal (RFP) process. Monitor closely, as a vendor’s performance at the RFP stage is often a strong indicator of future performance.

- Ongoing Risk Reviews:Once the vendor is hired, assess risk to monitor any variations in agreed-upon deliverables or processes. Ensure the vendor is preserving quality standards without generating loss to the company, investors, or customers. If any high-risk items occur, reassess the situation to decide if the relationship continues and determine if it’s possible to eliminate threat.

- Triggered Risk Reviews:Stay vigilant about your vendor’s status. Be on the lookout for bad press, financial problems, legal issues, and safety concerns that would trigger a risk review of current or potential vendors.

By performing vendor due diligence and monitoring, you can help mitigate risks and provide a solid foundation for productive relationships.

Leverage Vendor Tools and Technology

Specifications are essential to the construction process because they define in words what cannot be visualized or explained on a drawing. Unclear specifications between you and the vendor leads to errors and inefficiencies throughout your project.

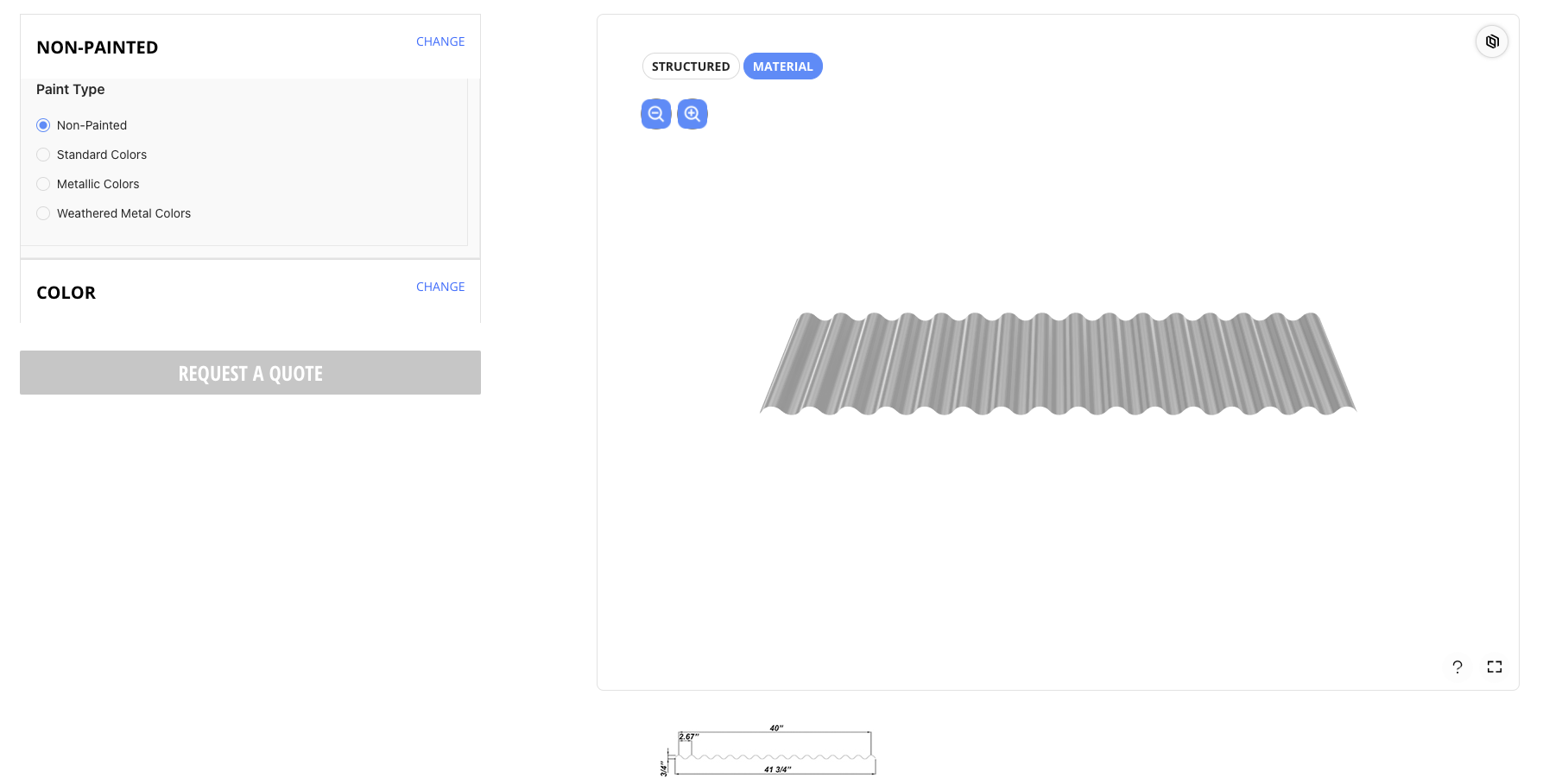

Take advantage of the tools your vendor offers to streamline the procurement process. For example, Corrugated Metal Inc.’s revolutionary new configurator tool enables you to choose from a vast range of product materials, finished, specifications, and metal capabilities to customize and visualize the exact products you need before ordering.

The ability to build and view materials before you buy ensures accuracy and confidence in your order.

Develop Strong Relationships

Alliances and relationships are fundamental in the construction industry. Having reliable and skilled vendors to support your organization can reduce downtime and increase productivity.

The opportunity for future work with you will motivate vendors to give their best on- and offsite, correct small mistakes quickly, and deliver higher service.

When you collaborate and involve your vendors in strategizing how to achieve your goals and expectations, it leads to valuable, long-term partnerships. Repeat business with a trusted vendor like Corrugated Metals Inc. enables you to work together like a well-oiled machine, get accustomed to each other’s attitudes and work styles, and ensure outstanding results.

Ready to learn how CMI’s experience and innovation will enhance your next project? Get in touch today.