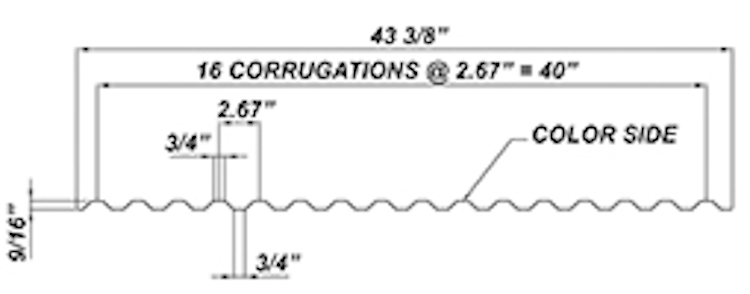

Cor-Rib

Our Cor-Rib roofing and siding panels are typically used for roofing, siding, custom trailers, railcars and other architectural applications.

Notes

- An asterisk (*) indicates allowable stress has been reached.

- A strikethrough (

100) indicates less than 10 small PSF ASCE minimum. - For structural roofing & siding made of formed metal sheets, a total load deflection shall not exceed L/60.

- Refer to Table 1604.3 limits and footnotes of the International Building Code (IBC) for additional guidance.

- Allowable spans and loads DO include self-weight of panel.

- All values are for one foot of panel width unless noted otherwise.

- Yield stress = Fy = 33,000 PSI.

- Loads and spans for carbon steel are based on AISI Standard for Design of Cold-Formed Steel Structure Members (2007 Edition).

- Yield stress = Fcy = 13,000 PSI.

- Loads and spans for aluminum are based on Aluminum Design Manual (January 2005).

PRODUCT CHARACTERISTICS

LOAD TABLE

| Section | Weight | Total Cross-Sectional

Area A (in2) |

Allowable Stress

Fa (psi) |

Top Flat in Compression | Bottom Flat in Compression | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sheet

lb/ft |

Area

lb/sf |

Moment of Inertia

I (in4/ft) |

Section Modulus

S (in3/ft) |

Allowable Moment

Ma (lb-ft/ft) |

Moment of Inertia

I (in4/ft) |

Section Modulus

S (in3/ft) |

Allowable Moment

Ma (lb-ft/ft) |

|||

| 18 Ga | 7.81 | 2.31 | 2.30 | 19760 | 0.029 | 0.103 | 170 | 0.029 | 0.105 | 174 |

| 20 Ga | 6.25 | 1.85 | 1.84 | 19760 | 0.023 | 0.084 | 138 | 0.023 | 0.086 | 142 |

| 22 Ga | 4.84 | 1.44 | 1.42 | 19760 | 0.018 | 0.066 | 108 | 0.018 | 0.068 | 112 |

| 24 Ga | 4.22 | 1.25 | 1.24 | 19760 | 0.016 | 0.058 | 95 | 0.016 | 0.060 | 98 |

| 26 Ga | 3.44 | 1.02 | 1.01 | 19760 | 0.013 | 0.047 | 78 | 0.013 | 0.049 | 81 |

| 0.02 Alum | 1.09 | 0.32 | 0.92 | 8069 | 0.012 | 0.043 | 30 | 0.012 | 0.045 | 30 |

| 0.024 Alum | 1.30 | 0.39 | 1.10 | 8403 | 0.014 | 0.051 | 37 | 0.014 | 0.053 | 37 |

| 0.032 Alum | 1.74 | 0.52 | 1.47 | 8500 | 0.019 | 0.068 | 49 | 0.019 | 0.070 | 49 |

TABLE 1: APPLIED LOAD (PSF)

An asterisk (*) indicates allowable stress has been reached.

| Table 1 | Applied Load (PSF) | |||||||

|---|---|---|---|---|---|---|---|---|

| Allowable Spans | 10 | 20 | 30 | 40 | 50 | 60 | ||

| Section | Span Limit | Span Type | Allowable Spans (ft) | |||||

| 18 Ga | L/60 | 1 Span | 8′-6″ | 7′-0″ | 6′-2″ | 5′-8″ | 5′-1″ * | 4′-8″ * |

| 2 Span | 9′-7″ | 7′-10″ | 6′-7″ * | 5′-9″ * | 5′-2″ * | 4′-9″ * | ||

| 3 Span | 9′-4″ | 7′-8″ | 6′-9″ | 5′-11″ * | 5′-4″ * | 4′-11″ * | ||

| L/240 | 1 Span | 5′-4″ | 4′-5″ | 3′-11″ | 3′-7″ | 3′-4″ | 3′-1″ | |

| 2 Span | 6′-0″ | 4′-11″ | 4′-4″ | 4′-0″ | 3′-9″ | 3′-6″ | ||

| 3 Span | 5′-10″ | 4′-10″ | 4′-3″ | 3′-11″ | 3′-7″ | 3′-5″ | ||

| 20 Ga | L/60 | 1 Span | 8′-0″ | 6′-6″ | 5′-9″ | 5′-2″ * | 4′-7″ * | 4′-3″ * |

| 2 Span | 9′-0″ | 7′-2″ * | 6′-0″ * | 5′-2″ * | 4′-8″ * | 4′-3″ * | ||

| 3 Span | 8′-9″ | 7′-2″ | 6′-2″ * | 5′-5″ * | 4′-10″ * | 4′-5″ * | ||

| L/240 | 1 Span | 5′-0″ | 4′-1″ | 3′-7″ | 3′-4″ | 3′-1″ | 2′-11″ | |

| 2 Span | 5′-8″ | 4′-7″ | 4′-1″ | 3′-9″ | 3′-5″ | 3′-3″ | ||

| 3 Span | 5′-6″ | 4′-6″ | 4′-0″ | 3′-7″ | 3′-4″ | 3′-2″ | ||

| 22 Ga | L/60 | 1 Span | 7′-5″ | 6′-0″ | 5′-3″ * | 4′-7″ * | 4′-1″ * | 3′-9″ * |

| 2 Span | 8′-4″ | 6′-5″ * | 5′-4″ * | 4′-8″ * | 4′-2″ * | 3′-10″ * | ||

| 3 Span | 8′-2″ | 6′-7″ | 5′-6″ * | 4′-10″ * | 4′-4″ * | 3′-11″ * | ||

| L/240 | 1 Span | 4′-8″ | 3′-10″ | 3′-4″ | 3′-1″ | 2′-10″ | 2′-8″ | |

| 2 Span | 5′-3″ | 4′-3″ | 3′-9″ | 3′-5″ | 3′-2″ | 3′-0″ | ||

| 3 Span | 5′-1″ | 4′-2″ | 3′-8″ | 3′-4″ | 3′-1″ | 2′-11″ | ||

| 24 Ga | L/60 | 1 Span | 7′-2″ | 5′-9″ | 4′-11″ * | 4′-4″ * | 3′-10″ * | 3′-6″ * |

| 2 Span | 8′-0″ | 6′-1″ * | 5′-0″ * | 4′-4″ * | 3′-11″ * | 3′-7″ * | ||

| 3 Span | 7′-10″ | 6′-3″ * | 5′-2″ * | 4′-6″ * | 4′-1″ * | 3′-8″ * | ||

| L/240 | 1 Span | 4′-6″ | 3′-8″ | 3′-2″ | 2′-11″ | 2′-8″ | 2′-7″ | |

| 2 Span | 5′-0″ | 4′-1″ | 3′-7″ | 3′-3″ | 3′-0″ | 2′-10″ | ||

| 3 Span | 4′-11″ | 4′-0″ | 3′-6″ | 3′-2″ | 3′-0″ | 2′-10″ | ||

| 26 Ga | L/60 | 1 Span | 4′-10″ * | 2′-10″ * | 2′-4″ * | 2′-1″ * | 1′-10″ * | 1′-8″ * |

| 2 Span | 4′-10″ * | 2′-10″ * | 2′-4″ * | 2′-1″ * | 1′-10″ * | 1′-8″ * | ||

| 3 Span | 4′-1″ * | 3′-0″ * | 2′-5″ * | 2′-1″ * | 1′-11″ * | 1′-9″ * | ||

| L/240 | 1 Span | 3′-0″ | 2′-5″ | 2′-1″ | 1′-11″ | 1′-9″ | 1′-8″ | |

| 2 Span | 3′-4″ | 2′-8″ | 2′-4″ | 2′-1″ * | 1′-10″ * | 1′-8″ * | ||

| 3 Span | 3′-3″ | 2′-7″ | 2′-4″ | 2′-1″ | 1′-11″ | 1′-9″ * | ||

| 0.02 Alum | L/60 | 1 Span | 4′-8″ | 3′-5″ * | 2′-9″ * | 2′-5″ * | 2′-2″ * | 2′-0″ * |

| 2 Span | 4′-10″ * | 3′-5″ * | 2′-10″ * | 2′-5″ * | 2′-2″ * | 2′-0″ * | ||

| 3 Span | 5′-0″ * | 3′-7″ * | 2′-11″ * | 2′-6″ * | 2′-3″ * | 2′-1″ * | ||

| L/240 | 1 Span | 2′-11″ | 2′-4″ | 2′-1″ | 1′-10″ | 1′-9″ | 1′-8″ | |

| 2 Span | 3′-4″ | 2′-8″ | 2′-4″ | 2′-1″ | 1′-11″ | 1′-10″ | ||

| 3 Span | 3′-3″ | 2′-7″ | 2′-3″ | 2′-1″ | 1′-11″ | 1′-9″ | ||

| 0.024 Alum | L/60 | 1 Span | 4′-11″ | 3′-9″ * | 3′-1″ * | 2′-8″ * | 2′-5″ * | 2′-2″ * |

| 2 Span | 5′-4″ * | 3′-10″ * | 3′-2″ * | 2′-9″ * | 2′-5″ * | 2′-3″ * | ||

| 3 Span | 5′-5″ | 3′-11″ * | 3′-3″ * | 2′-10″ * | 2′-6″ * | 2′-4″ * | ||

| L/240 | 1 Span | 3′-1″ | 2′-6″ | 2′-2″ | 2′-0″ | 1′-10″ | 1′-9″ | |

| 2 Span | 3′-6″ | 2′-10″ | 2′-5″ | 2′-3″ | 2′-1″ | 1′-11″ | ||

| 3 Span | 3′-5″ | 2′-9″ | 2′-5″ | 2′-2″ | 2′-0″ | 1′-11″ | ||

| 0.032 Alum | L/60 | 1 Span | 5′-5″ | 4′-4″ * | 3′-7″ * | 3′-1″ * | 2′-9″ * | 2′-6″ * |

| 2 Span | 6′-1″ | 4′-5″ * | 3′-7″ * | 3′-1″ * | 2′-10″ * | 2′-7″ * | ||

| 3 Span | 5′-11″ | 4′-6″ * | 3′-9″ * | 3′-3″ * | 2′-11″ * | 2′-8″ * | ||

| L/240 | 1 Span | 3′-5″ | 2′-9″ | 2′-5″ | 2′-2″ | 2′-0″ | 1′-11″ | |

| 2 Span | 3′-10″ | 3′-1″ | 2′-8″ | 2′-5″ | 2′-3″ | 2′-2″ | ||

| 3 Span | 3′-9″ | 3′-0″ | 2′-8″ | 2′-5″ | 2′-3″ | 2′-1″ | ||

TABLE 2: TRIAL SPAN (FT)

An asterisk (*) indicates allowable stress has been reached.

A strikethrough (100) indicates less than 10 small PSF ASCE minimum.

| Table 2 | Trial Span (ft) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Allowable Loads | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| Section | Span Limit | Span Type | Allowable Loads (PSF) | |||||||||

| 18 Ga | L/60 | 1 Span | 148 * | 82 * | 52 * | 32 | 19 | 12 | ||||

| 2 Span | 152 * | 84 * | 53 * | 36 * | 26 * | 18 | 12 | |||||

| 3 Span | 162 * | 90 * | 57 * | 38 * | 26 | 17 | 11 | |||||

| L/240 | 1 Span | 67 | 27 | 12 | ||||||||

| 2 Span | 96 | 39 | 19 | 10 | ||||||||

| 3 Span | 89 | 36 | 17 | |||||||||

| 20 Ga | L/60 | 1 Span | 120 * | 67 * | 42 * | 26 | 15 | |||||

| 2 Span | 124 * | 68 * | 43 * | 29 * | 21 * | 14 | ||||||

| 3 Span | 132 * | 73 * | 46 * | 31 * | 21 | 13 | ||||||

| L/240 | 1 Span | 54 | 21 | 10 | ||||||||

| 2 Span | 77 | 31 | 15 | |||||||||

| 3 Span | 71 | 29 | 14 | |||||||||

| 22 Ga | L/60 | 1 Span | 94 * | 52 * | 33 * | 20 | 12 | |||||

| 2 Span | 97 * | 54 * | 34 * | 23 * | 16 * | 11 | ||||||

| 3 Span | 104 * | 58 * | 36 * | 25 * | 16 | 10 | ||||||

| L/240 | 1 Span | 41 | 16 | |||||||||

| 2 Span | 59 | 24 | 11 | |||||||||

| 3 Span | 55 | 22 | 10 | |||||||||

| 24 Ga | L/60 | 1 Span | 83 * | 46 * | 29 * | 17 | 10 | |||||

| 2 Span | 85 * | 47 * | 30 * | 20 * | 14 * | |||||||

| 3 Span | 91 * | 51 * | 32 * | 22 * | 14 | |||||||

| L/240 | 1 Span | 36 | 14 | |||||||||

| 2 Span | 52 | 21 | 10 | |||||||||

| 3 Span | 48 | 19 | ||||||||||

| 0.26 Ga | L/60 | 1 Span | 18 * | |||||||||

| 2 Span | 18 * | |||||||||||

| 3 Span | 19 * | 10 * | ||||||||||

| L/240 | 1 Span | |||||||||||

| 2 Span | 14 | |||||||||||

| 3 Span | 13 | |||||||||||

| 0.02 Alum | L/60 | 1 Span | 25 * | 14 * | ||||||||

| 2 Span | 26 * | 14 * | ||||||||||

| 3 Span | 28 * | 15 * | ||||||||||

| L/240 | 1 Span | |||||||||||

| 2 Span | 13 | |||||||||||

| 3 Span | 12 | |||||||||||

| 0.024 Alum | L/60 | 1 Span | 31 * | 17 * | ||||||||

| 2 Span | 32 * | 18 * | 11 * | |||||||||

| 3 Span | 34 * | 19 * | 12 * | |||||||||

| L/240 | 1 Span | 11 | ||||||||||

| 2 Span | 16 | |||||||||||

| 3 Span | 14 | |||||||||||

| 0.032 Alum | L/60 | 1 Span | 42 * | 23 * | 12 | |||||||

| 2 Span | 43 * | 24 * | 15 * | 10 * | ||||||||

| 3 Span | 46 * | 25 * | 16 * | |||||||||

| L/240 | 1 Span | 15 | ||||||||||

| 2 Span | 21 | |||||||||||

| 3 Span | 19 | |||||||||||

Have questions?

Please fill out the form to contact us or call us at 1-800-621-5617.